L'azienda

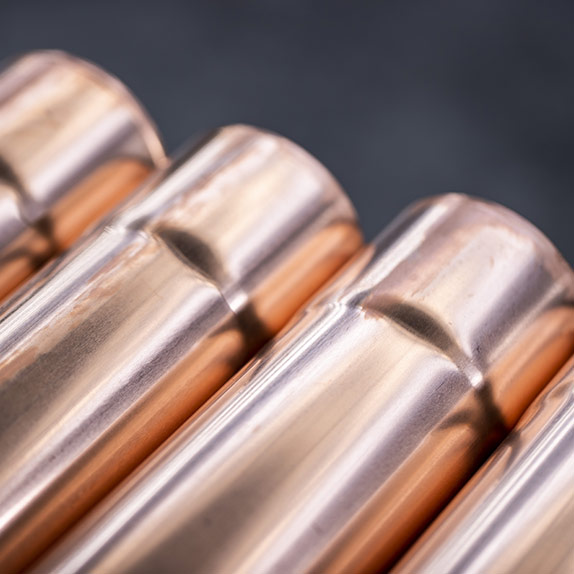

Silmet Spa, grande realtà industriale della metallurgia italiana fondata nel 1973, è parte del gruppo Ghidini ed è specializzata nella produzione di tubi di rame per l’industria, l’edilizia, l’idraulica e il settore medico.

Produzione

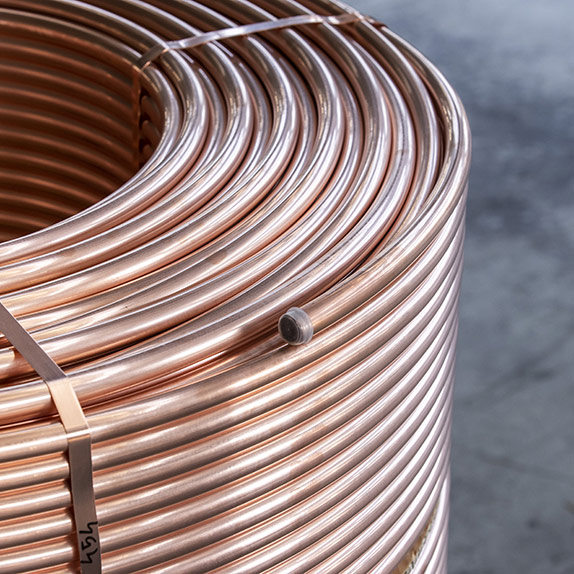

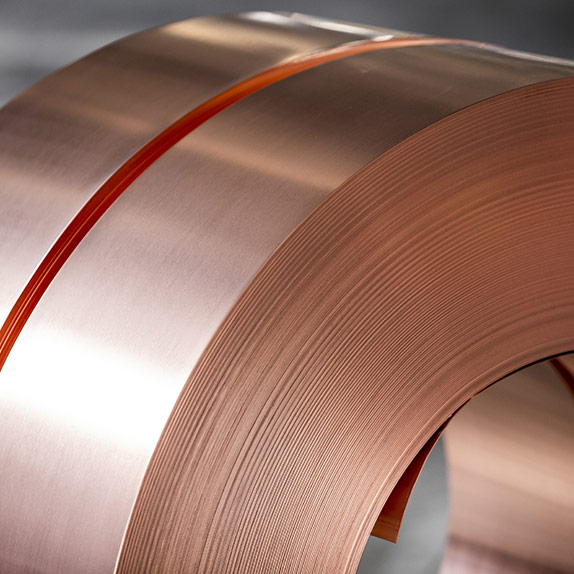

Silmet è leader nel mercato mondiale nella produzione di tubi in rame e di bobine Level Wound Coils per l’idrotermosanitaria e il settore industriale. La vasta gamma di prodotti che l'azienda produce spazia dai sifoni in ottone e plastica per idraulica, ai tubi e barre in ottone per svariati utilizzi industriali; piatti e fili di rame per uso edilizio ed elettrico; tubi in rame per applicazioni medicali.

Stabilimenti

Gli stabilimenti del Gruppo Ghidini sono tecnologicamente all’avanguardia e garantiscono la possibilità di modificare la produzione in funzione delle esigenze del cliente, in osservanza di tutte le normative mondiali di fabbricazione. Gli impianti dispongono di altiforni, grandi presse ad estrusione, potenti trafile e modernissimi forni di ricottura e normalizzazione del metallo.